Biogas-to-CNG Compression

Project Description

Stockholm, the capital of Sweden, has two sewage treatment plants, where biogas is produced to serve as fuel for the 120 inner city buses. The Henriksdal sewage treatment plant processes sewage water from the inner city and southern parts of Stockholm, resulting in an annual production of about 9 million Nm³ of raw biogas.

At this site, Malmberg, a Swedish contractor in the fields of water treatment and biogas, has supplied a biogas upgrade plant to produce around 6 million Nm³ of upgraded biogas per year.

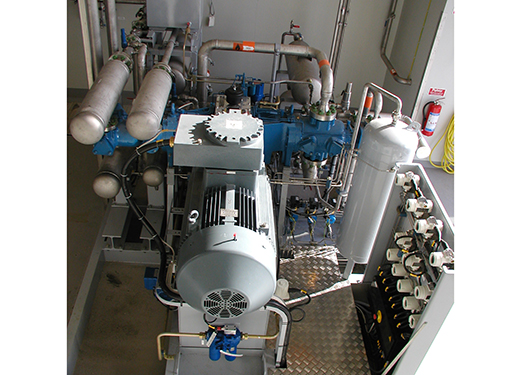

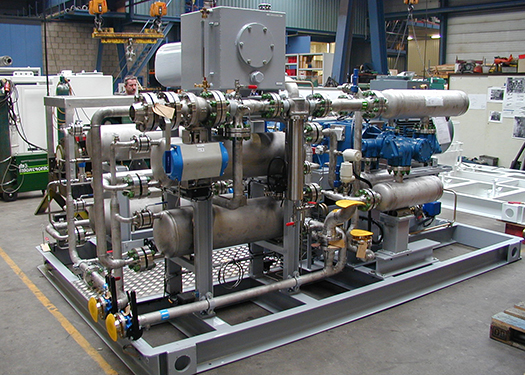

For this project, CSH has supplied a skid mounted electric driven 2-stage reciprocating compressor installation to compress the cleaned biogas to a storage pressure of about 350 bar.

Customer / End user:

Malmberg Water AB / Stockholm Water AB

Location:

Stockholm, Sweden

System capacity:

450 Nm³/h

Differential pressure:

340 bar(g)

Scope of supply:

One (1) skid mounted electric driven 2-stage reciprocating compressor package, comprising of:

- Ariel compressor, type JGP/2

- Electrical driver Eexde

- Inlet and discharge filters

- Gas interstage cooling for 1st, 2nd and 3rd stage

- Gas discharge cooling

- Condensate separator

- Oil lubrication system with circulation pumps and cooling

- Instrumentation for local and remote readout (signals hard wired to skid edge junction box)

- Suitable for hazardous area ATEX Zone 2, group IIB, class T3

- Factory Acceptance Test with site start up, commissioning, and Site Acceptance Test