Tail Gas Recovery

Project Description

The Danube Refinery has a vacuum distillation unit to separate the atmospheric crude tower residue to produce heavy, medium, and light gas oil as well as a vacuum residue. Waste gas generated at the vacuum process has a high sulfur and hydrogen sulfide content.

One part of the Danube Refinery Upgrade Project was to install two compressors for sending the vacuum tail gases, generated at the vacuum distillation units, in a common pipeline to the low pressure feed pipe of the Central Gas Processing Unit. Here the gas stream will be desulphurized, after which it is used as low sulfur fuel gas in the furnaces of the refinery.

Customer / End user:

Trans Lex Work Kft. / MOL Hungarian Oil and Gas Plc.

Location:

Danube Refinery – Szazhalombatta, Hungary

System capacity:

90 – 250 Nm³/h

Differential pressure:

2 bar(g)

Scope of supply:

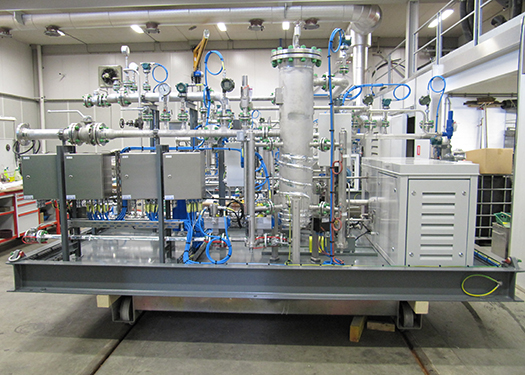

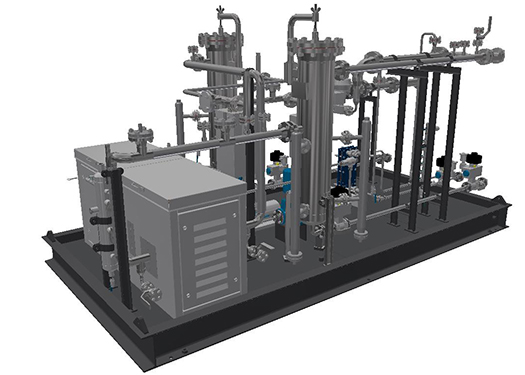

Two (2) skid mounted electric driven rotary vane compressor packages, each

comprising of:

- Ro Flo compressor, type 5CC

- Electrical driver with frequency drive

- Double mechanical bellow seals with pressurized seal oil system

- Lubrication system

- Inlet and discharge scrubbers

- Heat tracing and (noise) insulation

- Cooling water system

- F&G & ESD signals hard wired to skid edge JB’s

- Suitable for hazardous area ATEX Zone 1, Gas group IIA, T3

- Factory acceptance test with site start up, commissioning, and training activities