Biogas-to-CNG Compression

Project Description

Eskilstuna Energy & Environment (Eskilstuna Energi & Miljö) is a municipality owned company providing utilities to the district of Eskilstuna. The city of Eskilstuna is known for her environmental awareness and developments. Considering this, the company YIT Vatten & Miljöteknik AB received the order for the lumpsum turnkey delivery of a biogas upgrade installation at the nearby Ekeby sewage plant. The upgraded biogas is used as a fuel for the municipality’s city buses.

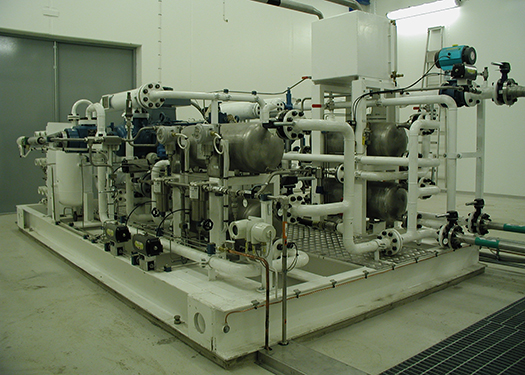

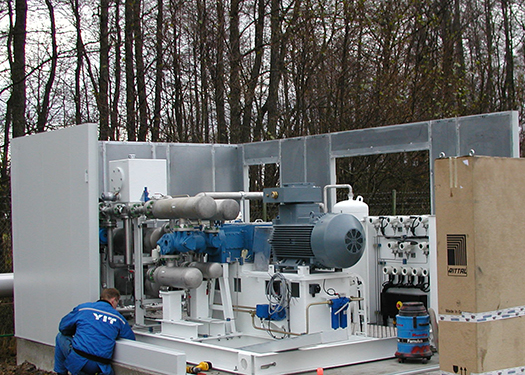

As part of this project, CSH supplied a skid mounted electric driven 2-stage reciprocating compressor installation, housed in a noise attenuated enclosure, to compress the cleaned biogas to a storage pressure of about 350 bar.

Customer / End user:

YIT Vatten & Miljöteknik AB / Eskilstuna Energi & Miljö

Location:

Eskilstuna – Sweden

System capacity:

450 Nm³/h

Differential pressure:

340 bar(g)

Scope of supply:

One (1) electric driven 2-stage reciprocating compressor package, installed in a noise attenuating enclosure, comprising of:

- Ariel compressor, type JGP/2

- Electrical driver Eexde

- Inlet and discharge filters

- Gas interstage cooling for 1st, 2nd and 3rd stage

- Gas discharge cooling

- Condensate separator

- Oil lubrication system with circulation pumps and cooling

- Instrumentation for local and remote readout (signals hard wired to skid edge junction box)

- Suitable for hazardous area ATEX Zone 2, group IIB, class T3

- Factory Acceptance Test with site start up, commissioning, and Site Acceptance Test