Fuel Gas Boosting

Project Description

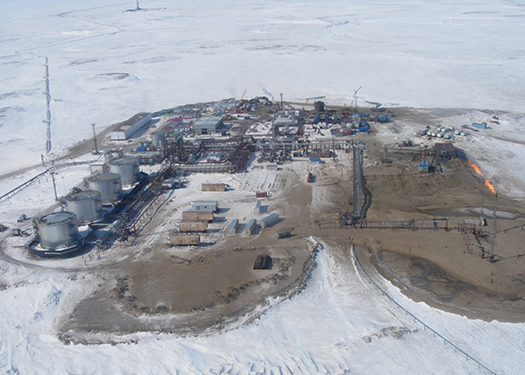

To reduce flaring of associated gases during production at the Vakhitovskoe oilfield, TNK-BP (nowadays Rosneft OSJC) has implemented an emission reduction project. Under this project BPC Energy has supplied in total six Opra gas turbines using untreated wellhead gas as fuel gas. The gathered wellhead gas was sent to the fuel gas boosters, increasing the fuel gas pressure to the level required by the gas turbines.

CSH has supplied in total four skid mounted, electric driven screw compressors to boost the wellhead gas to a pressure of 12 bar(g).

Customer / End user:

BPC Power Systems / Rosneft OJSC (former TNK-BP)

Location:

Vakhitovskoe field, Russia

System capacity:

731 Nm³/h

Differential pressure:

6 bar(g)

Scope of supply:

Four (4) skid mounted electric driven screw compressor packages, each comprising of:

- GHH compressor, type CU 90G

- Electrical driver Eexde with frequency drive

- Gas inlet scrubber, oil reclaimer tank

- Heavy duty gas discharge coalescing filters

- PLC-based control system for local and remote control

- Air cooled discharge cooler

- Suitable for hazardous area ATEX Zone 2G, Gas group IIB, T3

- Factory acceptance test with site start-up, commissioning, and site acceptance test