Fuel Gas Boosters

Project Description

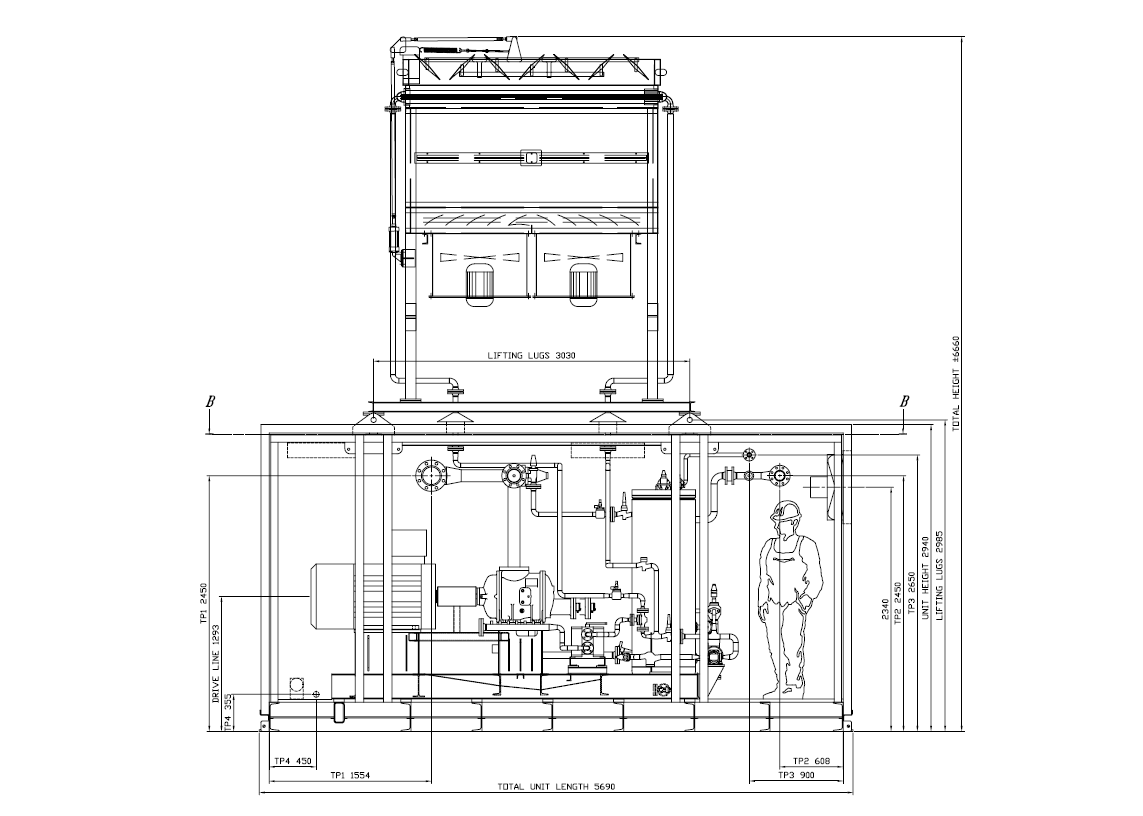

Two fuel gas boosters to increase the fuel gas pressure to the level required for a gas turbine or gas engine.

Application

Package design data:

MEDIUM: NATURAL GAS (free from dirt and liquid droplets)

Inlet pressure = 4 bara

Inlet temperature: +8°C

Outlet pressure = 13 bara

Nominal speed: 2975 rpm

Mass flow: 2592 kg/h

Suction flow: 831 am3/h

General package scope of supply

- Oil injected Howden rotary screw compressor Model WCV 163.145.26

- Motor, main drive FLSD 315 LA Leroy Somer 132kW, 400V, 50Hz, 3000rpm, IM B3, IP55, II2G Eex d II B T4

- Frequency Controller MDS 180T-IP21 Leroy Somer EN954-1, IP21, incl. main switch, 400V, 3ph, Heavy duty 132 kW, 76 +/- 2 dB(A)

- Oil separator T61, 22 bar, 0/+120 °C Design AD2000 (CE/PED), Nobo: TUV

- Double oil filter, incl. 3 way change over valve Duplex Filter BFD 100.260.02-DN25-GJS400-18 Boll & Kirch Filtration from inside to outside, incl 25 mu paper start-up filters (2 off)

- Oil pump MNP 36/36 HYDROLUB Maag ATEX certified, 69 ltr/min, overflow valve 8 bar

- Air-cooled oil cooler Type 14/14-2C15-HT-25 Bronswerk Heat Transfer

- PLC + Profibus Siemens S7-300 Profibus: 6ES7 314-6CG03

- Valves and instrumentation

- All mounted into a 20 ft container

Contact

For more information, please contact our sales team at csh@compressorsystems.com or +31 347 324610.