Fuel Gas Boosting

Project Description

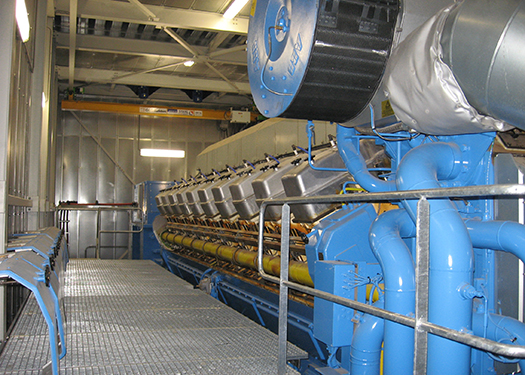

Hortipower is a tomato grower in Merksplas in Belgium with 15 hectares of green houses. For lighting and heating the glasshouses, an investment was made in a combined heat and power plant by means of a Rolls Royce gas engine. The generated electricity is supplied to the green house lighting and the surplus is supplied to the Belgian electricity grid. The engine’s cooling water is used to heat the greenhouses and CO2 from the exhaust gases is blown into the greenhouses to accelerate the growth process of the tomatoes.

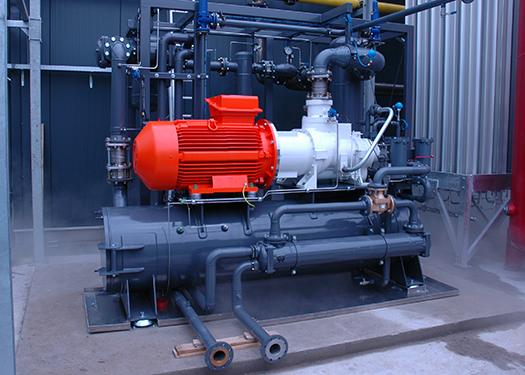

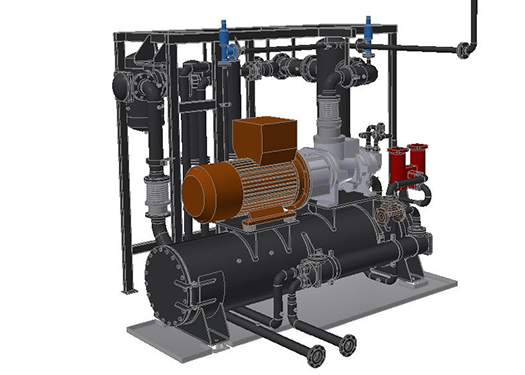

However, the pressure in the existing gas grid was insufficient to feed the new gas engine. CSH has delivered a skid mounted Fuel Gas Booster, installed in a noise attenuating enclosure, to increase the fuel gas pressure from 0.5 to 4.5 bar(g).

Customer / End user:

Hortipower BvBa

Location:

Merksland, Belgium

System capacity:

2050 Nm³/h

Differential pressure:

4 bar(g)

Scope of supply:

One (1) electric driven oil injected rotary screw compressor package, comprising of:

- Gardner Denver compressor, type SSQG

- Electrical driver Eexna with Frequency drive

- PLC control system for local and remote control

- Lubrication oil system with oil reclaiming vessel, cooler, control valve and cartridge type filter

- Heavy duty gas inlet and outlet filtration

- Discharge gas cooler

- Drop over type, noise attenuating enclosure (<70 dB @ 1 m)

- Suitable for hazardous area ATEX Zone 2G, Gas group IIB, T3

- Factory acceptance test with site start up, commissioning, and site acceptance test