Fuel Gas Boosting

Project Description

Heineken’s brewery in Zoeterwoude, The Netherlands, has two anaerobic digesters producing biogas, fueling a local gas engine. To maximize utilization of the biogas, Heineken decided to divert the biogas stream to two local gas turbines, up till then entirely fed by natural gas from the national gas grid. It was determined to mix the natural gas with upgraded biogas, by injecting the upgraded biogas in the fuel gas supply line of the gas turbines. This solution provided an annual natural gas saving of 2.5 Mm3

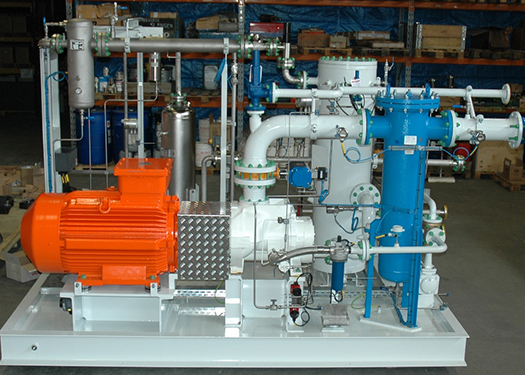

To enable this, CSH delivered a skid mounted Fuel Gas Booster, installed in a noise attenuating enclosure, to increase the fuel gas pressure from 0.6 to 24 bar(g).

Customer / End user:

Heineken Nederland B.V.

Location:

Zoeterwoude, The Netherlands

System capacity:

425 Nm³/h

Differential pressure:

23.4 bar(g)

Scope of supply:

One (1) electric driven oil injected rotary screw compressor package, comprising of:

- Gardner Denver compressor, type SSMG

- Electrical driver Eexde

- Lubrication oil system with oil reclaiming vessel, cooler, control valve and cartridge type filter

- Heavy duty gas inlet and outlet filtration

- Water-to-Gas discharge gas cooler

- Drop over type, noise attenuating enclosure (<80 dB @ 1 m)

- Instrumentation signals hard wired to skid edge JB’s for remote monitoring and control

- Suitable for hazardous area ATEX Zone 2G, Gas group IIB, T3

- Factory acceptance test with site start-up, commissioning, and site acceptance test