Fuel Gas Boosting

Project Description

P3P is an organization that develops, operates and maintains both their own and third party sites in the energy, waste and vertical farming sectors in the United Kingdom. For one of their customers, APS Group, on the Isle of Wight, P3P developed a dedicated energy center to provide heat, power and CO2 to the onsite glasshouses. The project consisted of two 5.5 MWe Rolls Royce gas engines and associated CO2 and heat recovery equipment.

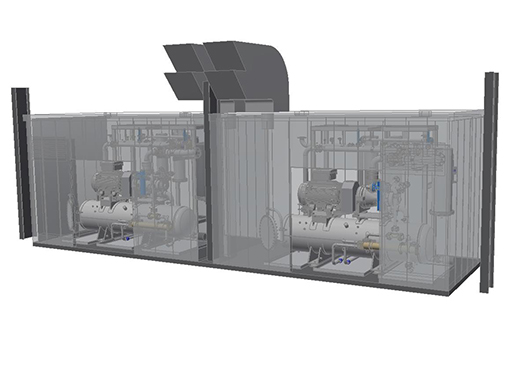

To overcome the low pressure in the national gas grid, fuel gas boosting was required. CSH delivered two skid mounted Fuel Gas Boosters, installed in a noise attenuating enclosure, to increase the fuel gas pressure to 5 bar(g).

Customer / End user:

P3P Partners LLP / Harvest Generation Services Ltd.

Location:

Newport, Isle of Wight, United Kingdom

System capacity:

1250 Nm³/h

Differential pressure:

5 bar(g)

Scope of supply:

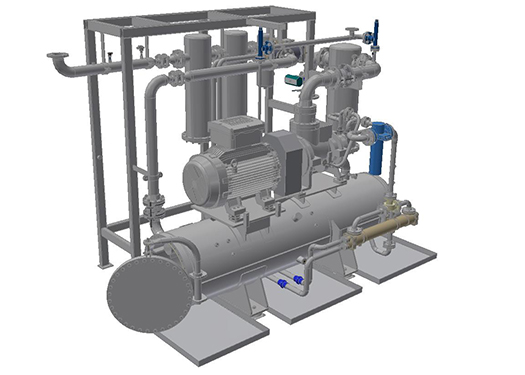

Two (2) electric driven oil injected rotary screw compressor package, comprising of:

- Gardner Denver compressor, type SSQG

- Electrical driver Eexna with Frequency drive

- PLC control system for local and remote control

- Lubrication oil system with oil reclaiming vessel, cooler, control valve and cartridge type filter

- Heavy duty gas inlet and outlet filtration

- Discharge gas cooler

- Drop over type, noise attenuating enclosure (<70 dB @ 1 m)

- Suitable for hazardous area ATEX Zone 2G, Gas group IIB, T3

- Factory acceptance test with site installation, commissioning, and site acceptance test