Green Gas Grid Injection

Project Description

To increase the sustainable development and reduce the environmental footprint, Penare farm in Higher Fraddon, United Kingdom, decided to invest in a biogas plant. An anaerobic digester converts organics material including local food waste and agricultural waste, into gas and electricity. Gas is fed into the national grid and to a local CHP to produce heat and electricity, ensuring proper operation of the plant. Per hour 450 Nm3 raw biogas is upgrade to 250 Nm3 biomethane. Equivalent to the consumption of natural gas by 2000 households.

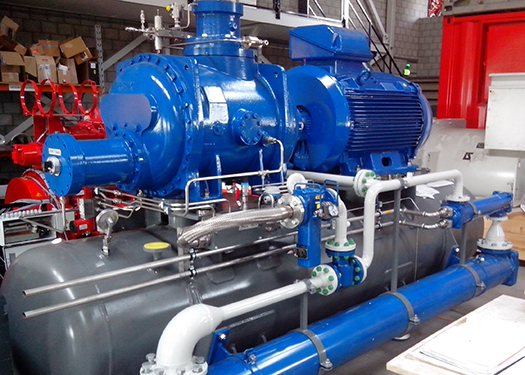

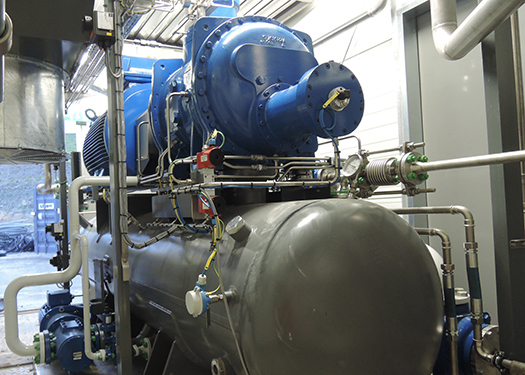

DMT Environmental Technology supplied the biogas upgrade installation, to export the Green Gas to the national grid and fuel the CHP installed on site. For this project, CSH delivered an oil injected rotary screw compressor package, which we installed in DMT’s biogas upgrade enclosure.

Customer / End user:

DMT Environmental Technology B.V. / Fraddon Biogas Ltd.

Location:

Higher Fraddon, United Kingdom

System capacity:

1570 Nm³/h

Differential pressure:

16.5 bar(g)

Scope of supply:

One (1) skid mounted electric driven oil injected rotary screw compressor packages, comprising of:

- Howden compressor, type WRVi 255-130 58

- Electrical driver EexnA with frequency drive

- Inlet and discharge filters

- Gas cooling system

- Condensate separator

- Oil cooling system

- PLC-based control system for automatic compressor operation

- Suitable for hazardous area ATEX Zone 2, group IIB, class T3

- Factory Acceptance Test with site start-up, commissioning, and Site Acceptance Test