Green Gas Grid Injection

Project Description

Four farmers in the West Jutland region of Denmark founded the company Vestjysk Biogas ApS to supply Green Gas, produced from slurry, deep litter and chicken manure at their farms, to the national gas grid in Denmark. Lundsby Biogas designed and developed the project, for which DMT Environmental Technology supplied a biogas upgrade installation.

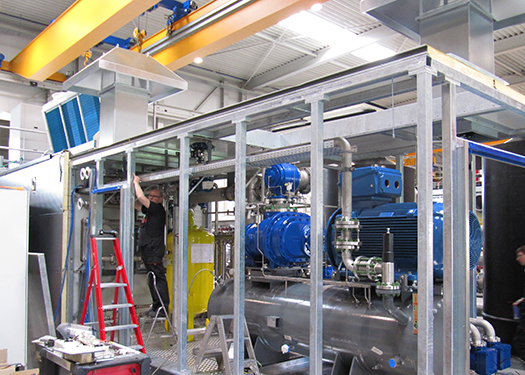

CSH supplied an oil injected rotary screw compressor package, installed in DMT’s biogas upgrade enclosure, to transfer the upgraded gas through a 4.5 km long transmission line to the main natural gas station in the village Bølling, Denmark. From here, five million tons of gas are fed into the natural gas grid per year.

Customer / End user:

DMT Environmental Technology B.V. / Vestjysk Biogas ApS

Location:

Borris, Denmark

System capacity:

2100 Nm³/h

Differential pressure:

17 bar(g)

Scope of supply:

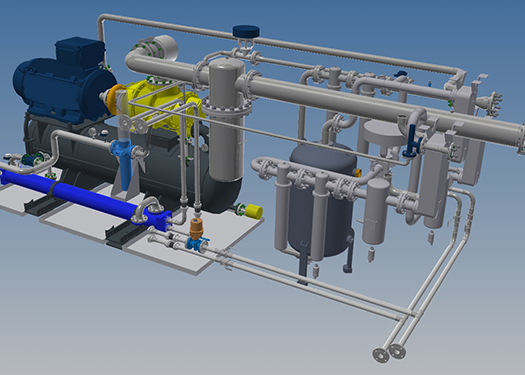

One (1) skid mounted electric driven oil injected rotary screw compressor packages, comprising of:

- Bauer Rotorcomp compressor, type EVO76

- Electrical driver EexnA with frequency drive

- Inlet and discharge filters

- Gas-to-Gas super heater

- Gas-to-Water sub- and discharge cooling system

- Condensate separator

- Oil cooling system with waste heat recovery

- PLC-based control system for automatic compressor operation

- Suitable for hazardous area ATEX Zone 2, group IIB, class T3

- Factory Acceptance Test with site start-up, commissioning, and Site Acceptance Test