Refrigerant Charging & Vapor Recovery

Project Description

At the Mina Abdulla refinery of Kuwait National Petroleum Company (KNPC) a standalone thermosyphon refrigeration system was installed by Petrochemical Industries Company (PIC) for the Aromatics Offplots Project. The refrigeration system contained propane (R290) as refrigerant.

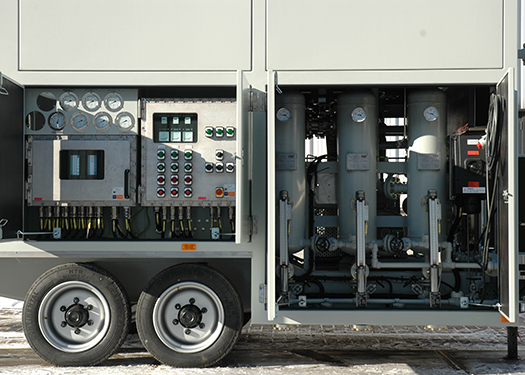

For this remote located installation, PIC was looking for a mobile solution that could fill and (partially) empty the refrigeration system for start up and maintenance activities. CSH has supplied a custom built, trailer mounted solution, based on a 2-stage reciprocating compressor, suitable for operation in a Class I, Division 2 hazardous environment.

Customer / End user:

Petrochemical Industries Company (PIC) / Kuwait National Petroleum Company (KNPC)

Location:

Mina Abdulla Refinery, Kuwait

System capacity:

Maximum 166 Nm³/h

Differential pressure:

19 bar(g)

Scope of supply:

One (1) trailer mounted electric driven 2-stage reciprocating compressor system, comprising of:

- 1x Corken compressor, oil free, type T391

- 1x Corken liquid transfer pump, type CORO

- 1x Rotary vane vacuum pump

- 3x Electrical driver Eexde

- 2x Air cooled gas cooler

- 3x Inlet knock out drums

- Compressor/pump control panel

- Air cooled discharge cooler

- Suitable for hazardous area Class 1, Division II, Gas group D, T3

- Factory acceptance test with site start up, commissioning, and site acceptance test