Vapor Recovery

Project Description

Dutch shipping company Chemgas is active in the transportation of pressurized chemicals and Liquefied Petroleum Gas (LPG). With a unique sea and river going fleet, Chemgas is capable of transferring LPG up to 3500 m³.

Instead of venting gases to the atmosphere, Chemgas installs Vapor Recovery Compressor Installations that convert the gas back to a liquid. Apart of minimizing the ‘escape’ of harmful emissions, the shipment volume is maximized as well.

Customer / End user:

Chemgas Shipping B.V.

Location:

Multiple inland barges

System capacity:

160 – 2844 Nm³/h

Differential pressure:

5 bar(g)

Scope of supply:

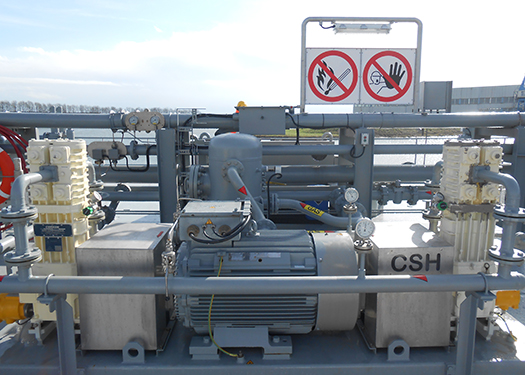

Per vessel or barge one (1) skid with dual mounted electric driven 1-stage reciprocating compressor package, comprising of:

- 2x Corken vertical compressor, type D981

- 1x Electrical driver Eexde with two drive ends

- 1x Nitrogen purge system

- Suitable for hazardous area ATEX Zone 1, Gas group IIC, T4

- Bureau Veritas marine type certification

- Factory acceptance test with site start up and commissioning